The development of industrial manufacture has speeded up in recently years, with a wider application of industrial robots. And as an electronic equipment to mimic human movements, slip rings and electrical rotary joints must be installed to enable an agile rotation of the mechanical parts while maintaining a reliable signal transmission.

JINPAT Electronics is a provident slip ring manufacturer that took the lead in entering the industrial robot field. JINPAT Slip Rings for Automatic Welding Machine is a national patent winning product. JINPAT keeps doing research and development for the industrial production industry. Our products range from super mini size ones to large volume high power slip rings.

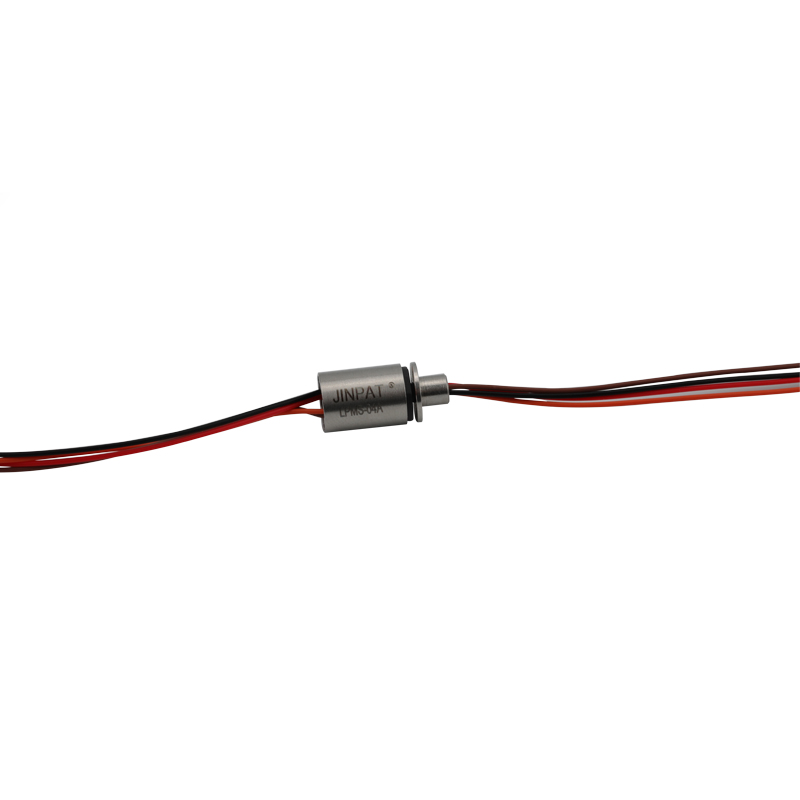

Let’s take a look at the super miniature slip ring specially designed for robotic arms in the manufacturing industry. It is a special type of slip ring developed from JINPAT LPMS super miniature slip ring. An extra aluminum alloy pole is added to facilitate its installation and operation on the robotic arms. Representative slip ring models: LPMS-04A and LPMS-06A.

Different from the small robotic devices, the medium/large size industrial robots have a higher standard on slip rings. Capability to transmit special signals, fluid and gas are also necessary in industrial production robots. And most of these robots tend to have a long operating time. Therefore, slip rings must be versatile enough and reliable in performance to fit in these kind of devices. JINPAT has industrial slip rings with case housing that can provide more protection to the slip ring unit. Besides, our slip ring products adopt well-laid inner structure which can guarantee an excellent electronic performance and a long service life.

For more slip ring solutions and related products like rotary unions and rotary joints, please visit JINPAT’s website page. Feel free to contact JINPAT for a quotation and consultation.