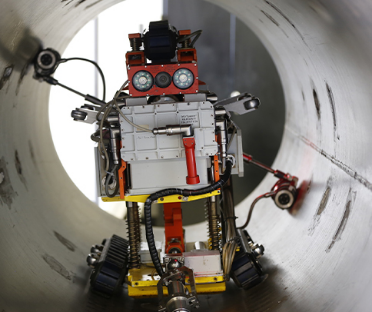

Pipeline system is an important basic infrastructure of a city. Pipelines are laid underground, containing certain cables and communication equipment. And these pipe need regular inspection. However, given the limited space, it is difficult for people to carry out inspection in person. Pipe robots are invented to solve this problem. And on this appliance, there is a need to transmit signal from the 360-degree rotary camera to the control and process center. Therefore, a slip ring is needed to enable rotary transmission of power and signals.

JINPAT Electronics has produced several slip ring model types especially for pipe robots.

To begin with, LPT025-0420-0607 and LPT000-0213 are two slip ring models that transmit only power. There are many channels and thus able to transmit large current. They are applied in middle-size and large-size pipe robot. To be more specific, these through bore slip rings are generally installed in the cable reel of the control center.

Besides, there are also hybrid slip rings for sewer robots that can transmit power and signals at the same time. LPT000-3816-2002-04S features having lots of power channels and signal channels. There are 38 16A power channels, 20 2A channels and 4 specialized signal channels. The power channels adopt FLRY as leads and shielded twisted pairs for signal transmission.

As for small-size pipe robot, LPC-24A-0216-0202, LPC-18A-01-0802-HD01, LPMS-06B-06S and LPM-12F-0802-HD01 are the major slip ring models being chosen. Take LPMS-06B-06S electrical slip ring for example, there are 2 signal channels, 1 analog video signal channel and 2 channels for other signals. LPM-12F-0802-HD01 is a hybrid slip ring model with capability to transmit high definition video signals. Slip rings as these can be installed on the camera joint on the pipe robots. They are compact in size and with high protection grade.